Best Practices: Order Cancellations

You work hard to get a PO, secure a contract, win the bid for the job, and get the order. So much work goes into winning the sales game, and then you need to kick off the process of scheduling the job, buying the materials, and even start work and track time…

And then it happens: the customer calls and has to cancel. Maybe their own customer’s order fell through. They could be dealing with revision changes, or need to tighten up their spending. Situations like this happen all the time.

Or, maybe you find a quality issue late in the production process. You released the wrong documents, or you found an issue at final inspections. It’s too late to just put the parts back on the shelf. But you can’t complete and close the order, not to mention ship it. What do you do?

Whatever the cause may be, understanding how to cancel an order is important. What are your options in Cetec ERP? What are the best practices to ensure you capture all the details and financial impact, and mitigate any potential fallout?

There’s a few different scenarios to consider here:

1/ A customer is canceling their order, and the part is already mostly constructed and past the point of being able to disassemble for parts. You have raw material inventory and labor tied up into that build, and it’s passing inspections. Maybe you can sell the item elsewhere, or ship it to the customer later.

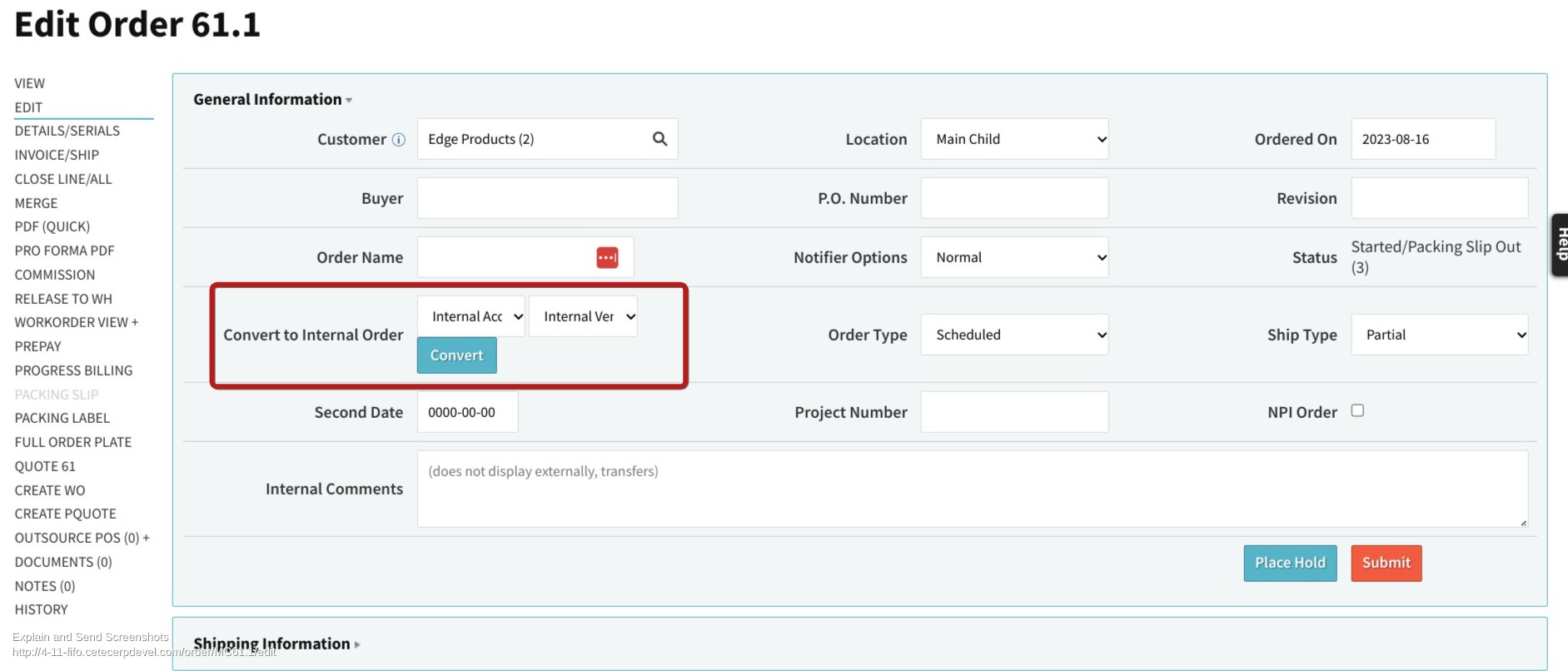

The right thing to do here is to convert the external build order to an internal, build-to-stock order. For a guide to converting orders from build orders to stock orders, check out our post.

Next, finish the production process and complete/receive the product into your finished goods. Doing so ensures the raw material inventory is backflushed/consumed, and the labor is posted to the ledger. This then gives you a finished good item that you can either scrap, or keep in stock to ship on a different/future order.

2/ You need to cancel the order, but rather than deal with the finished goods, you just want to delete the order. In this scenario, you need to determine if parts are picked or not.

-

If no parts are picked, then you can simply close the order.

-

If parts are picked, then you need to decide what to do with those pieces. Can they be returned to the shelf, or do they need to be scrapped?

-

If parts are picked, and they do not need to be scrapped, then you should dekit the order before closing.

-

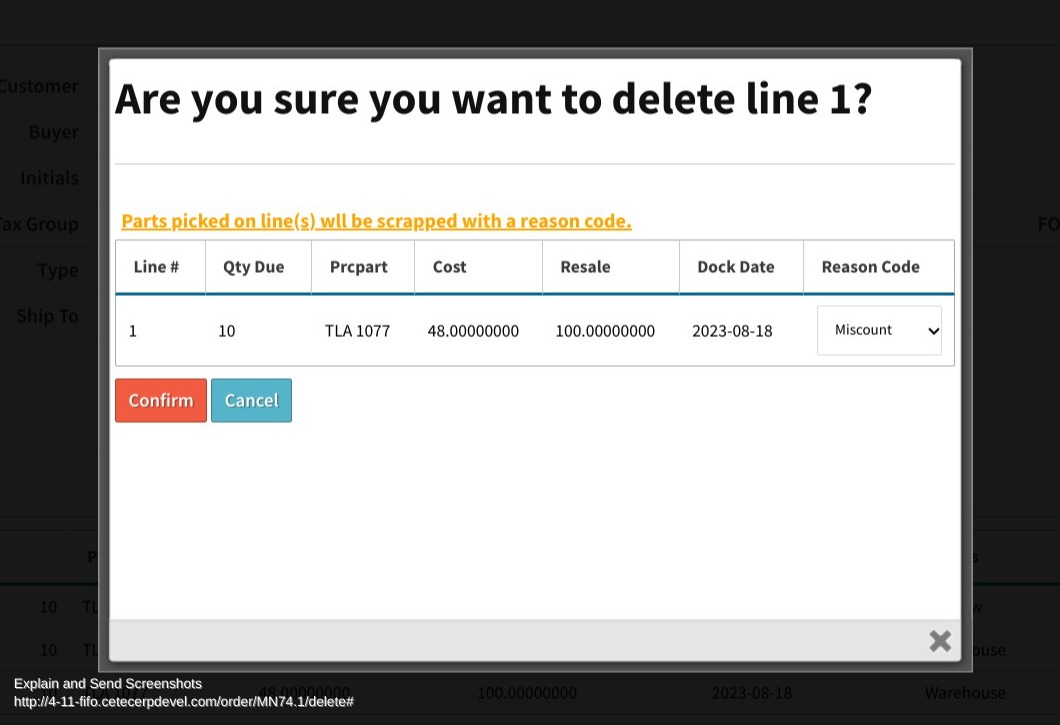

If parts are picked, and you are scrapping them, then you can go straight to the Order close screen. Select the lines to cancel. Cetec ERP will give a popup splash screen that allows you to choose the inventory adjustment code to record the scrap. This will scrap the parts and close the order.

The final step is dealing with any purchase orders placed for this order. To do this, your purchasing team should be regularly running what we call ‘Reverse MRP’. To view “Reverse MRP, you will run your Purchase Orders report, with the “View by” filter set to “PO Line”. Next, click the “More Options” at the bottom of the filters box, and you will see a filter called “Days Early”. The first box next to the “Days Early” sign allows you to filter by “<”, “>”, “=”, and “(No Need Date)”. Select the option “(No Need Date)”. This will show all PO lines without any orders driving a demand. For more information on Reverse MRP, check out our guide.

With Cetec ERP, you can easily cancel or convert orders based on your needs. A detailed walkthrough of the order cancellation process is available on our blog.